MBAA TQ: Managing Dissolved Oxygen in the Brewery

A few years ago, we did a lot of research on managing dissolved oxygen (DO) while transferring and packaging beer. The data found that a lot of beer was aging pre-maturely because of pickup from brite tanks, transfer hoses, and packaging lines. With careful oxygen management, the lifespan of a beer can easily be extended by many months. One brewery found their IPA’s shelf-life extending from about 1 month to 6 months!

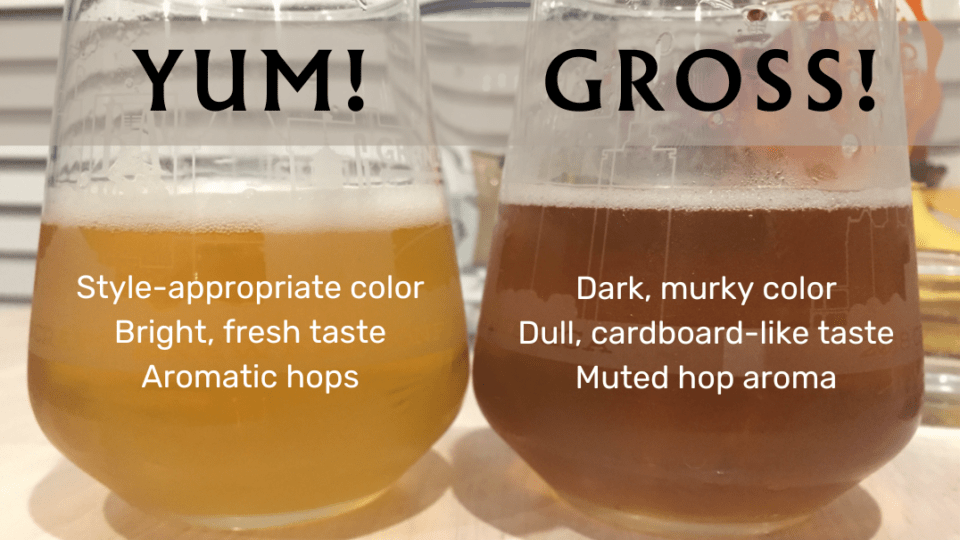

The speed at which oxygen can be introduced and trapped within a product is often grossly underestimated. While it make take days to weeks for the reactions to occur and the oxidation to be noticable, it only takes miliseconds of exposure for a significant amount to be picked up. One fish-eye bubble can turn a can’s straw-colored lager dark, mute the hop aroma compounds, and add a cardboard or sherry-like taste.

Taking precautions to avoid oxygen exposure and extend a beer’s shelf-life is relatively easy. Read Audrey’s Master Brewers Association of the Americas Technical Quarterly article below to learn more about reducing dissolved oxygen pickup during production and packaging.

Abstract

The shelf life of a beer can be impacted by many variables, but onw of the biggest influences across breweries, beer styles, and production methods is oxygen exposure. Oxidation can impart many undesirable qualities in a beer, and it does not take a lot of contact with air to start these reactions. Methods brewers can employ to reduce potential oxygen pickup around the brewery are discussed.

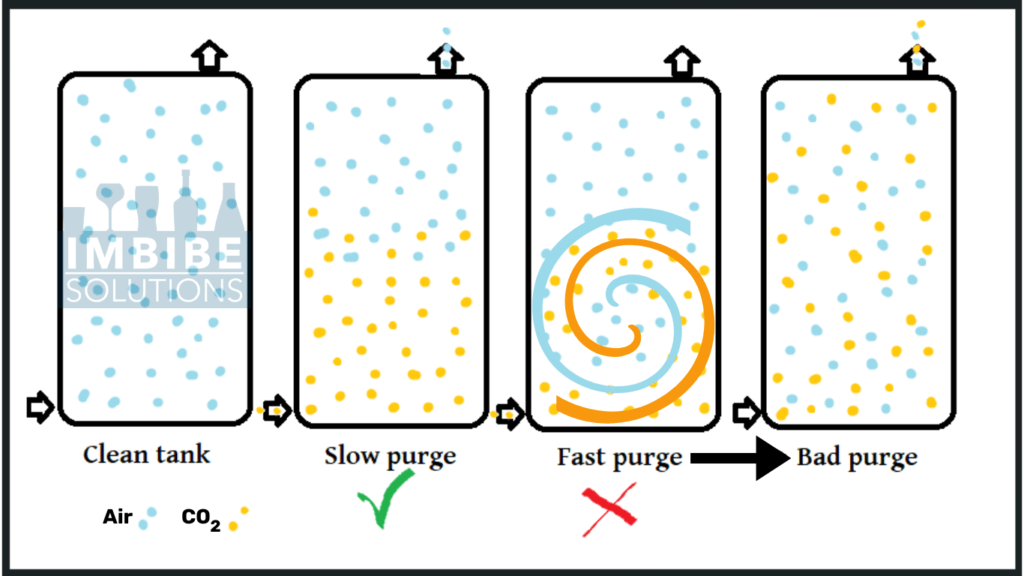

The purge should be conducted at a low pressure (5 psi is recommended) for a long period of time (3-4 h for a 30 barrel tank, or roughly 1 h per 10 barrels). Low pressure, slow flow, and sufficient time are very important and should not be ignored.

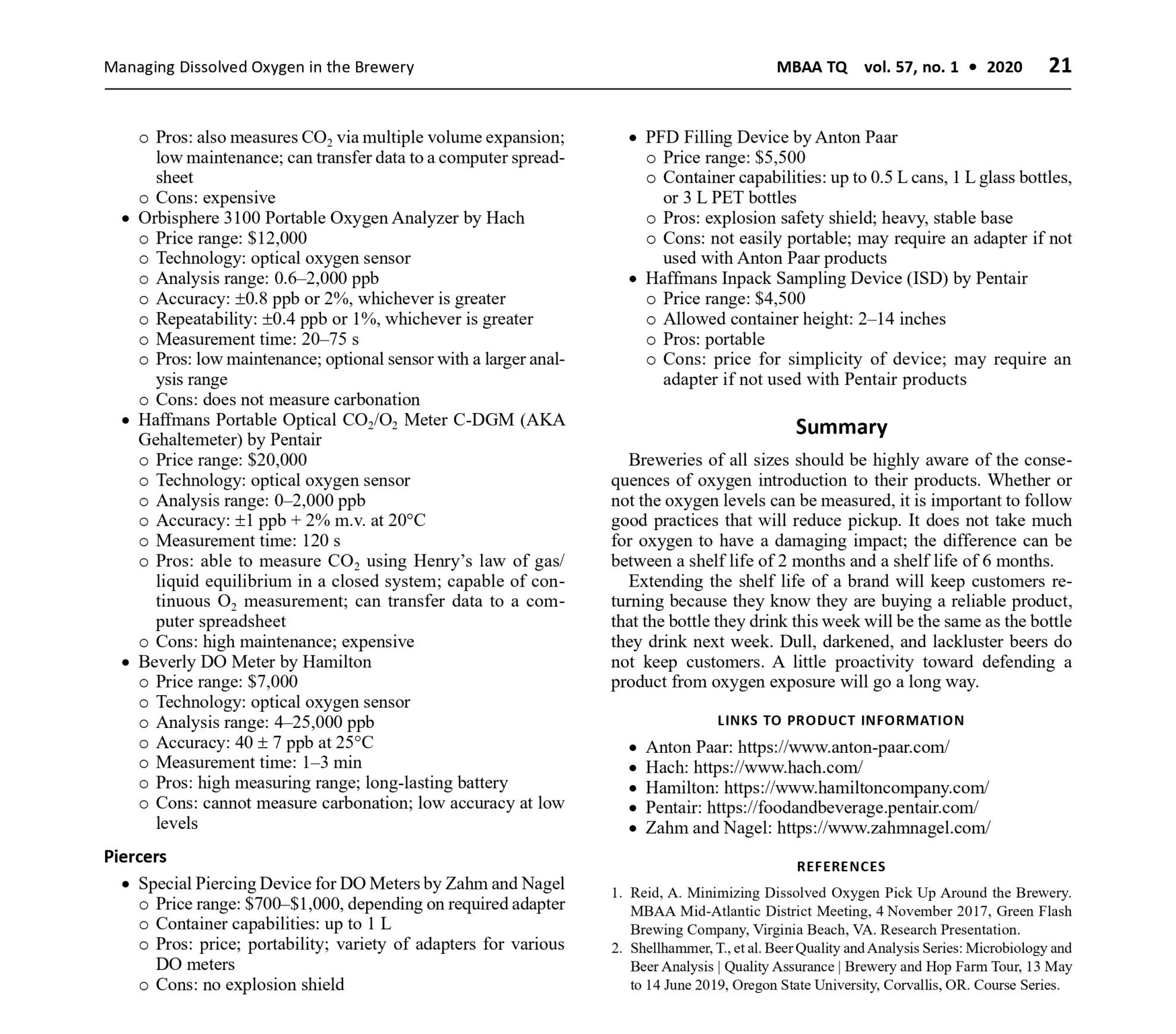

The goal is to have less than 50 ppb (ug/L) of oxygen present in the final package.

*Prices reflect research conducted in 2019.

Since oxygen reacts so quickly, the measurement process must be started on packages as soon as they come off the canning or bottling line. If the package is allowed to sit before starting the measuring process, the reading will be artificially low.

What did you think? Did you pick up any tips you can apply to your own facility? Need some on-site help?

If you have any questions, we would be happy answer them!