Malolactic Magic: Diving into the science of MLF

What is Malolactic fermentation?

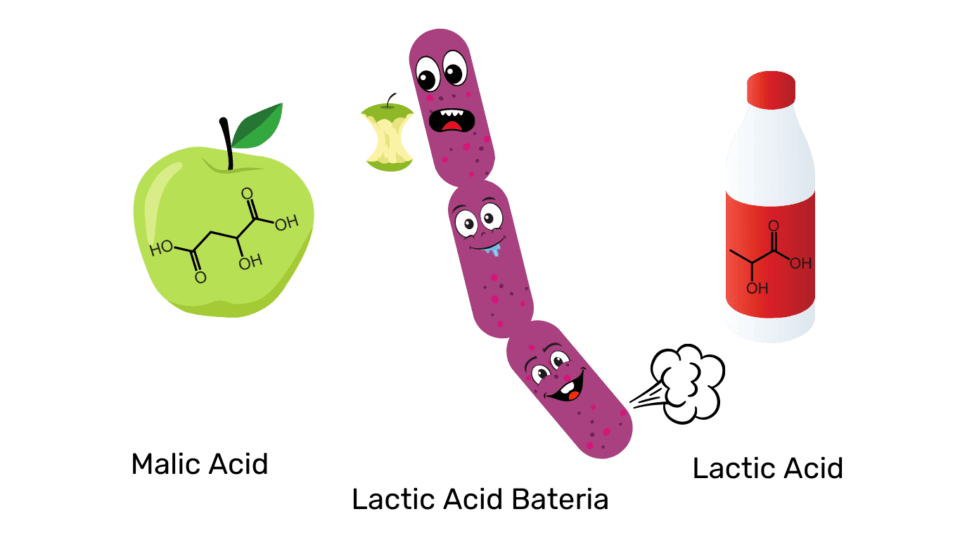

In a nutshell, Malolactic Fermentation (MLF) occurs when Lactic Acid Bacteria (LAB) convert malic acid into lactic acid. Multiple kinds of bacteria can be used for MLF. The most common bacteria used for malolactic fermentation are Oenoccoccus Oeni, Pediococcus, and Lactobacillus–talk about a mouthful!

Malolactic fermentation is primarily a stylistic choice. While most winemakers add these bacteria artificially, some can also be found naturally. It’s common to find these bacteria on grape skins or wine equipment, for example, used oak barrels. While we prefer to have control of whether or not a wine goes through malolactic fermentation, it can sometimes be out of the winemaker’s control. Malolactic fermentation, like many other aspects of winemaking, can be unpredictable. Bacteria are living things and, if there is one thing we know, living things don’t always follow the rules!

Fun Fact

The lactic acid found in milk is the same as the lactic acid produced during MLF!

Why bother?

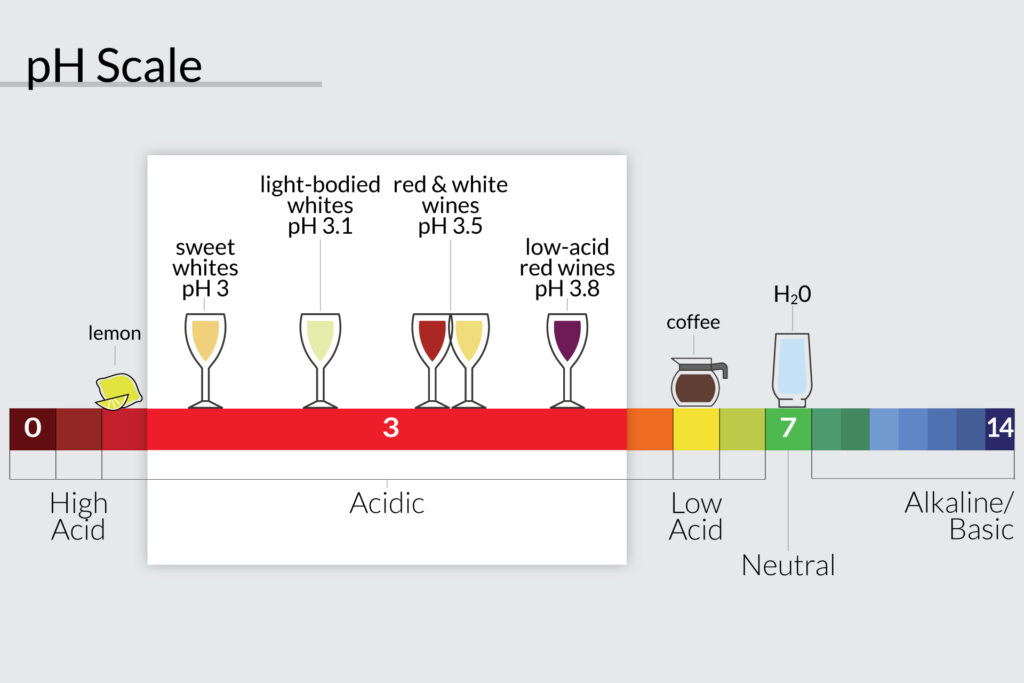

Malolactic fermentation is a useful tool in the winemaking process. While it may seem like just another tedious step, its impact can make all the difference by reducing acidity, enhancing flavor, and improving stability. Most reds and some whites (like Chardonnay and Viognier) go through malolactic fermentation due to their higher acid levels.

- Acid Reduction: Since lactic acid (a monoprotic acid) is less harsh than malic acid (a diprotic acid), malolactic fermentation both effectively and perceptually reduces acidity. Winemakers–be careful here! Too significant a decrease in total acidity can sometimes create an environment more prone to spoilage. In this case, winemakers should re-acidify the wine by adding an acid not metabolized by bacteria – something like tartaric acid.

- Flavor: Malolactic fermentation softens the tarter, fruitier flavors in wine. Mellowing the acidic tones makes for a buttery, creamy wine with a smooth texture. In general, MLF can make a wine taste deeper and more complex.

- Stability: When wines undergo malolactic fermentation before bottling, it prevents unwanted malolactic fermentation from happening in the bottle. If secondary fermentation does happen in the bottle, the wine will become “foggy” due to high levels of bacteria. In some cases, the wine can even develop sparkling undertones.

When should it happen?

When’s the best time for malolactic fermentation? Technically, malolactic fermentation can happen before, during, and after yeast fermentation (primary fermentation). However, this process is most commonly performed after primary fermentation is completed.

- Before: When malolactic fermentation is done before alcoholic fermentation, it can result in increased levels of volatile acidity (VA). Too much VA in the wine can lead to off-flavors if not properly managed. It can also interrupt the primary fermentation process, oftentimes creating stuck yeast fermentations.

- During: Some wines can undergo malolactic fermentation alongside primary fermentation. Performing malolactic fermentation during primary fermentation may also lead to higher levels of VA in the final product. Warning: Excessive amounts of VA can interfere with the primary fermentation process by competing for nutrients with the yeast. But wait, there’s a plus side! Cofermenting is much more time efficient and allows winemakers the option of adding sulfur dioxide sooner rather than later.

- After: The most common practice is for winemakers to initiate malolactic fermentation after primary fermentation is complete. The ML bacteria will “eat” all leftover nutrients during malolactic fermentation thereby limiting other microbial growth later on. Despite this benefit, performing malolactic fermentation after primary fermentation can also have its downsides. As a result of primary fermentation, the alcohol and sulfur dioxide produced by the yeast can inhibit the bacteria from converting malic acid into lactic acid. It’s simple: dysfunctional bacteria = no malolactic fermentation.

When deciding when to do malolactic fermentation, it is important to take all of these factors into account.

Let’s dive a little deeper…

- Diacetyl: Diacetyl is a byproduct of malolactic fermentation. At lower concentrations, diacetyl gives the wine a nutty, earthy flavor. At higher concentrations, diacetyl gives the wine a more buttery flavor. The amount of diacetyl produced by malolactic fermentation depends on citric acid concentrations, sulfur dioxide concentrations, oxygen concentrations, and pH.

Fun Fact

Diacetyl is one of the compounds responsible for the buttery aroma, flavor, and mouthfeel in certain Chardonnays.

- Acetic acid: A small increase in acetic acid concentration may occur during MLF and should not be considered an indication of spoilage. But be aware…high concentration increases may signify the presence of acetic acid bacteria which can cause the wine to adopt a vinegary (and really unappetizing) taste.

- Acetaldehyde: A nutty, bruised apple-like flavor that often results from oxidation can be “cleaned up” during MLF. One of the metabolic pathways of lactic acid bacteria conveniently consumes acetaldehyde and can eliminate it completely from the wine. Total degradation may take 2-10 days after MLF is complete.

- Lactic Acid Bacteria: As discussed earlier, there are many types of LAB that can be used for malolactic fermentation. Different strains will have varying effects on the flavor profile and speed of malic acid conversion. MLF can take anywhere from two to eight weeks.

Preventing Malolactic Fermentation

Sometimes, winemakers will try to prevent malolactic fermentation from occurring to maintain high acidity levels. Certain strategies can be used to avoid or limit malolactic fermentation.

- Cool Temperatures: Malolactic fermentation cannot be carried out at temperatures lower than 68 degrees Fahrenheit. Winemakers can use temperature control as a tool to keep their wine cold in order to prevent malolactic fermentation.

- Low pH: Bacteria also require a certain pH level to properly function. If pH levels are too low, malolactic fermentation cannot occur. Measuring the titratable acidity and pH will allow the winemaker to adjust the pH accordingly to control the LABs.

- Free SO2: Another method includes the supplementing of sulfur dioxide. Sulfur dioxide at low pH has been shown to be very effective at inhibiting lactic acid bacteria, allowing acidic aromas to keep their influence.

- Filtration: Using filtration to remove all the LAB cells is also a very effective method. Not only does this help prevent malolactic fermentation, but it also has a lot of other benefits. For more information on bottling, check out our next blog.

Now that we have outlined what malolactic fermentation is, when it happens, some pro and cons, go out into the world and make some informed winemaking decisions!