Case Studies

Jump to

With years of experience under our belts, we’ve learned a thing or two. Here are some of the ways we’ve applied our analyses to real-world problems. Our data-driven processes have helped many producers craft better products. Take a look for yourself!

Beer Case Study: 01

Shelf Life Extension

Problem: After only 1 month, the flavors had degraded and the beer no longer tasted bright and fresh.

Imbibe’s Solution: Dissolved oxygen evaluation and process adjustments at the brite tanks and canning line.

Result: An IPA that is still bright and hoppy 4 months after production.

Part of Imbibe’s mobile lab is on-site can, bottle, and tank testing for dissolved oxygen (DO) and carbonation. Using an Anton Paar CBox, we can hook directly up to a tank, pump, or centrifuge, or pair it with a piercer to test products as they come off the line. Oxidation reactions occur rapidly, so it is important to test as soon as possible after potential oxygen exposure.

For example, if testing the DO level in cans, the readings you would get from a can just sealed versus a can sealed ten minutes prior would be significantly different. The oxygen present will instantly start bonding (oxidizing) with other compounds, thereby reducing the amount of ‘free’ oxygen in suspension, which is read as DO. Some companies will let you send in cans/bottles for DO testing, and chances are the results are going to be very good. However, that doesn’t mean there wasn’t a high DO level; once oxygen is introduced, the damage can’t be undone. Readings that take place off-site are not reliable because there will have been plenty of time for the beer to oxidize. Beware any DO testing that doesn’t happen on-site.

We go into breweries to get a baseline reading on the cans/bottles, and we often find that the DO reading is quite high: 1,000 ppb and up. The goal is to be under 50 ppb, ideally as close to 0 ppb as possible. Over a couple sessions, we are able to work with the line manager to make minor adjustments that significantly reduce DO pick-up. Depending on the type of packaging line, there are different settings, parts, and mechanisms that can be altered, and we’ll walk you through it all. It may seem tedious, but it is well worth the time to produce a more stable, better tasting product.

Beer Case Study: 02

Hop Creep

Problem: Dry-hopped beers were significantly overshooting their target ABV.

Imbibe’s Solution: ABV monitoring pre and post dry-hopping to estimate average hop creep for core beers.

Result: Avoided excess spending on raw materials and costly fines by the state and federal regulatory agencies. Recipes were adjusted to accommodate for hop creep and are now able to nail their target ABV.

The last thing any producer needs is a fine from a state or federal regulatory agency. For beers, ABV must be within +/- 0.3% of the claimed value. That isn’t a lot of wiggle room. Sure, hydrometers can assist you in calculating the anticipated ABV, but all too often we have found those calculations to be off. This is especially true for beers that are either dry-hopped, high alcohol, or barrel aged.

Why are dry-hopped beers an issue? Because hops contain enzymes which reduce complex sugars to simple sugars causing yeast to restart fermentation.* This phenomenon is called Hop Creep. In fact, hop creep causes so much re-fermentation that it is possible for beers to go up 0.75% ABV! Way outside of the +/- 0.3% allowance.

What we do is monitor clients’ core and seasonal beers for average ABV increase due to dry-hopping. They can then adjust their recipes to shoot for a lower pre-dry-hop target ABV, knowing that the hop creep will add the rest. Not only does this keep their ABVs within the acceptable range to prevent hefty fining, it also helps them lower production cost. Since most dry-hopped beers overshoot their ABV, brewers are able to reduce the amount of malt they put into the mash in order to lower their pre-dry-hop target ABV. Less money in with the same amount produced means more profit.

As a note: Hop creep will also add a significant amount of diacetyl and carbonation, threatening to turn a beer into a literal “butter bomb.” To prevent this, make sure to let the beer mature on the yeast until the diacetyl is below 0.1 ppm (mg/L) and has finished its natural carbonation cycle. No one likes a good beer going buttery or a packaged beer exploding.

*We acknowledge that this is not proper English and don’t care.

Beer Case Study: 03

Exploding Cans

Problem: Customers were complaining about exploding cans.

Imbibe’s Solution: Check for microbial contamination via plating and PCR.

Result: Diastaticus was identified as the re-fermenting culprit.

Saccharomyces cerevisiae var. diastaticus is a mean little bugger. It has the capability to ferment some starches and complex sugars; so long after your chosen yeast strain goes dormant from lack of food, this guy is still going. It doesn’t take much for one cell to become many, meaning there is a huge potential for problems. There may even be no sign that they are present; a beer may reach the expected terminal gravity and appear to stop. However, as the species reproduces, the gravity will start dropping again – it just might be after the product has already been packaged. Introduce: exploding cans. The excess carbonation that builds up will make the can ends pop and then one day, BOOM! Everything smells like beer. Not the worst thing…but still.

As diastaticus becomes more of an issue in breweries, it is important to conduct regular testing. Even major breweries have had issues, and the species is hard to eradicate once present (see Left Hand Brewing’s story – they had to shut down for two weeks). It is also important to talk with your yeast supplier about strains or blends that may contain diastaticus. Many saison yeasts contain diastaticus. Some common examples are: White Labs French Saison Ale Yeast, Lallemand Belle Saison Belgian Yeast, and Wyeast Belgian Witbier. If you want to know more about diastaticus, check out the Milk The Funk Wiki page.

We conduct diastaticus screenings via PCR (DNA detection) and work with multiple breweries to test every beer going to packaging. In addition to testing for diastaticus, we also run PCR for Brettanomyces species and hop resistant Lactobacillus and Pediococcus. On multiple occasions we have prevented a contaminated beer from being placed in the market; helping companies avoid embarrassing recalls and reputation damage. It is a quick test that can save a fortune, so why not play it safe?

Beer Case Study: 04

Butter Beer

Problem: The beer was developing a slickness and tasted of butter.

Imbibe’s Solution: Test for the presence of diacetyl.

Result: The beer had a concentration of diacetyl above the 0.1ppm sensory threshold. The beer had not been allowed to mature long enough before being crashed.

Diacetyl is a natural by-product of yeast fermentation. It has the flavor and aroma of butter or butterscotch and a slick mouthfeel. If a beer is allowed to mature on the yeast, the yeast will eventually reabsorb the diacetyl and turn it into a neutral compound. Even if a terminal beer has no sign of containing diacetyl, the precursor may still be present. With time, the precursor will eventually turn into diacetyl, taking a perfectly good beer and making it buttery. Many breweries do a force test to check that a beer has matured on the yeast long enough. This involves heating a sample to convert the precursors and smelling it. With overly hoppy beers or beers with adjuncts, the diacetyl may be hard to perceive.

Testing for diacetyl in a lab (often called a VDK test) is an easy alternative to know that the concentration is below perceptible levels and ready for crashing. The sensory threshold of diacetyl is 0.1ppm (mg/L), so anything above that is considered diacetyl positive; meaning the beer is not done maturing. While adding a couple extra days to production may be extremely annoying, creating a high quality product is more valuable than a faster turnaround. Remember quality over quantity.

Beer Case Study: 05

Microbial Contamination – Preventing a Recall

Problem: Nothing apparent, initially.

Imbibe’s Solution: Perform microbial contamination checks on every batch.

Result: A beer with excessive levels of Pediococcus was withheld from the market and competition.

This beer tasted good. It tasted really good. So good, it was headed straight for the competition circuit. But first, as part of this brewery’s standard quality control procedure, it underwent microbial testing for hop resistant Lactobacillus, hop resistant Pediococcus, and S. diastaticus. The Pediococcus test came back with maximum contamination on the test scale.

That didn’t make any sense; there were no off-flavors typical of Pediococcus and to be that contaminated there should have been something. Right? We tested it again. Still highly contaminated.

Turned out, the beer was cold enough to keep all of the Pediococcus dormant so no off-flavors had yet been produced. However, they couldn’t risk sending it out into the market – let alone to competitions – inevitably it was going to warm up and that Pediococcus was going to take off. The very tasty beer was going to be ruined into something undrinkable and unrepresentative of the company.

Dumping 90 barrels of beer hurts; it isn’t cheap. Sending a bad beer to market, paying for a recall, staining your reputation, and losing customers, hurts more. Avoid recalls; know your product is stable and represents the best of your company; check every batch for spoilers.

Wine Case Study: 01

Bentonite Fining

Problem: The bottled white wine was showing a haze making it less visually appealing. No off-flavors or aromas were present.

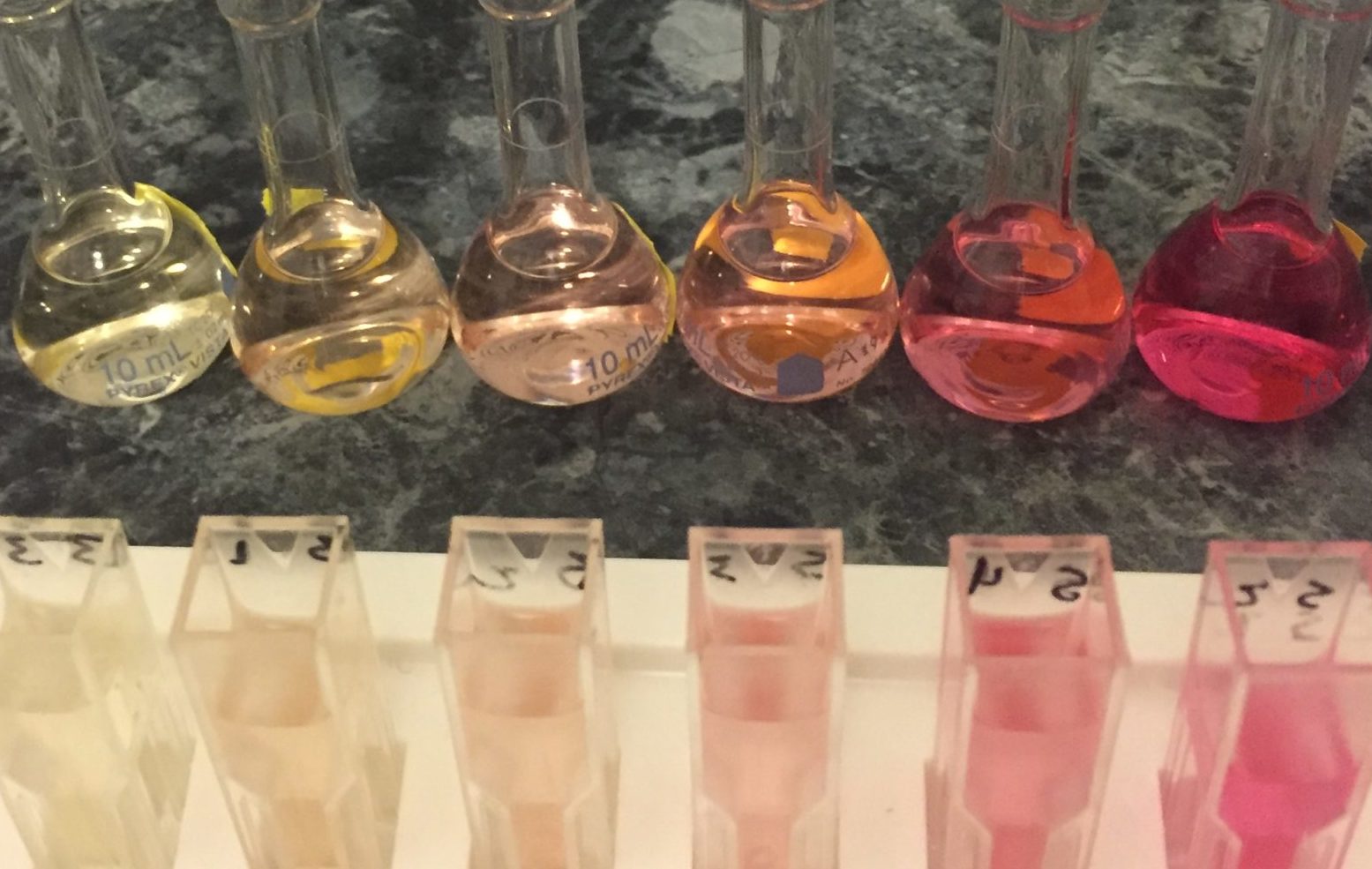

Imbibe’s Solution: Setting up bentonite trials with the sample of the bentonite being used by the winery to ensure the addition rate is accurate.

Result: White and Rose wines are heat stable in the bottle and no longer produce a protein haze.

Bentonite is a natural product that is mined from around the world. This means that each lot of bentonite is unique and should not be used at set rates. In the United States, it is very common that bentonite is a sodium-based clay, which has been found to have a greater binding rate than bentonites from other countries.

At Imbibe Solutions, we will set up a bentonite trial using your house-chosen product to report the accurate interaction between the wine and the fining product. We will measure the change in turbidity after exposing the sample to heat to help the winemaker determine the appropriate add rate to achieve stability without overfining and stripping the wine of delicate flavors and aromas.

Wine Case Study: 02

Volatile Acidity

Problem: The wine has a volatile acidity above the legal limit.

Imbibe’s Solution: Testing the wine regularly to catch an increasing volatile acidity before the detection threshold.

Result: Through actively monitoring volatile acidity, the winemaker was able to take proactive steps to prevent the acetic acid from accumulating above the legal limit in their products.

Volatile acidity is a term that encapsules a handful of acids that can be steam distilled. It is often measured and reported as acetic acid, the main volatile acid present in wine (>93%). Acetic acid is a biproduct of yeast and bacteria during fermentation, so it is normal to have certain levels in finished wine. Immediately post-fermentation, a wine would be expected to contain less than 0.5 g/L. Measuring the volatile acidity at the end of fermentation sets a base line for the acetic acid present as the wine goes through the aging process.

During aging, there are multiple benefits to testing the volatile acidity every few weeks. One of the main benefits is using it as a tool to monitor active spoilage organisms in the wine. Waiting until the volatile acidity can be detected organoleptically (about 0.8 g/L) is often too late to stop the spoilage organism that is causing the spike in acetic acid. By monitoring regularly, we are able to identify rapid spikes in volatile acidity and likely microbial spoilage before it can be perceived. This allows the winemaker to take proactive steps before the volatile acidity is detectable.

Wine Case Study: 03

Yeast Assimilable Nitrogen (YAN)

Problem: The winemaker was constantly battling spoilage organisms in their wines.

Imbibe’s Solution: Yeast Assimilable Nitrogen (YAN) was measured in the wine and found to be high – thus supplying a food source for unwanted organisms. The following harvest, YAN was measured at the juice stage allowing the winemaker to make additions accounting for the nitrogen already present in the juice.

Result: The proper amount of nitrogen was added during fermentation which left very little for spoilage organisms to consume and ended the constant battle.

To complete fermentation, yeast must obtain certain nutrients from their environment. Saccharomyces spp. require carbon (sugars), nitrogen, oxygen, sterols and lipids, minerals and vitamins. For nitrogen, they cannot use the nitrogen in the air so the juice must have assimilable nitrogen. At Imbibe, we can measure the yeast assimilable nitrogens which are amino acids and ammonia. More research is showing the previous notation that 250 ppm was needed to complete fermentation is too broad and that multiple factors need to be taken into consideration.

The first step is to take a measurement of the YAN right before the juice is inoculated. The winemaker can then use the measurement in conjunction with other factors like yeast strain, initial Brix, and stylistic goal to determine what additions the juice will require. The winemaker will be like Goldilocks, not too much to feed spoilage organisms, not too little to starve the yeast and stall the fermentation, but just the right amount to grow happy little yeasties.