The Brewing Process

How the four elements come together

and make music in your pint glass!

By Stephen Moxley

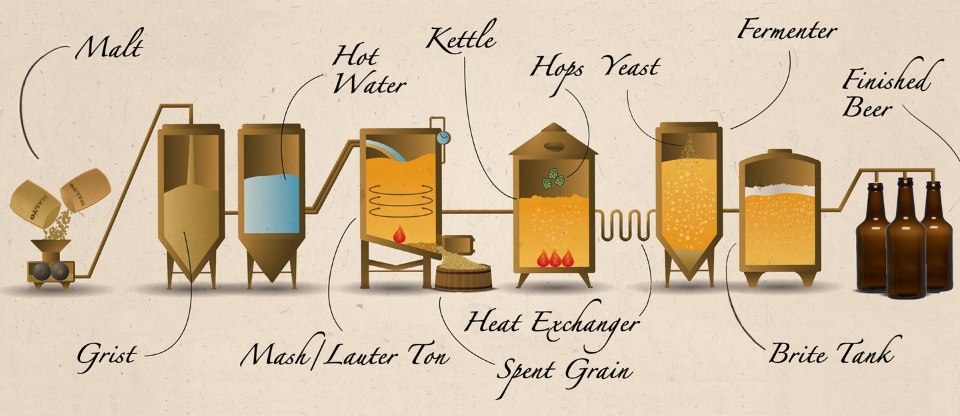

The world of beer is a wide one. As one of humanity’s oldest beverages, many cultures around the globe have their own brewing style and tradition. But how do the four elements of beer—malt, water, hops, and yeast—come together to make the perfect brew? Let’s follow the path these ingredients travel in the brewing process and watch them emerge on the other side as one!

Malt

The beginning of the brewing process starts with beer’s first element: malt. Malt is what provides the sugar for the yeast to eat and turn into alcohol. It also provides beer’s body and mouthfeel, in addition to providing nutrients for the yeast. When malt arrives at the brewery, it needs to be milled before it can be used. Milling breaks open the individual grains, exposing the starchy interior. In addition, milling removes some of the hulls, which is the tough, papery exterior of the grain. These hulls will be helpful later, because they help filter the wort when it comes time for the lauter.

Water

After milling, malt is combined with beer’s second ingredient: water. During the mash, hot water is combined with the malt at a specific temperature in a vessel called the mash tun. The temperature of the mash is usually between 148 and 158 F. This step is critical since it’s when the starch in the grain is converted to sugar. Yeast cannot consume starch, so without the mash there would be no sugars and therefore no alcohol!

What is wort?

Wort is the name for the sweet liquid drawn off from the grain in the mash. These sugars provide the carbohydrate source that yeast ferment into ethanol. As the saying goes, brewers just make wort, it’s the yeast that makes the beer!

This conversion takes place because of amylase enzymes present in the malt, which snip off sugar units from the long chains of starch. In addition to the conversion of starch to sugar, many other chemical changes occur to the malt compounds in the mash that prepare the wort for the next step in the process.

After mashing, which usually is about an hour long, the sweet wort must be separated from the grain through lautering. During this process, the liquid is slowly drawn off from under the grain so that all the solids are left behind in the mash tun. At larger breweries, the entire mash is pumped to a separate vessel where this occurs, known as the lauter tun. At smaller breweries, however, the mash and lauter both occur in one vessel, which is known as a combination mash-lauter tun (MLT).

Hops

Major chemical changes during the boil

- Inactivation of malt enzymes

- Sterilization of the wort

- Extraction and isomerization of compounds derived from hops

- Coagulation of protein material in the wort

- Formation of protein-polyphenol complexes

- Formation of flavor and color complexes

- Formation of reducing substances that may prevent oxidation in the final beer

- Drop in wort pH

- Concentration of wort gravity through evaporation of water

- Evaporation of volatile compounds from malt and hops.

Once the clarified wort is separated from the mash, it travels to the boil kettle, where the third beer element is added: hops. Hops provide necessary bitterness to beer in the form of alpha-acids. These compounds are converted to iso-alpha-acids during the boil, which are more potent and are responsible for the bitterness of the final product. This conversion step needs time, so hops that are added at the beginning of the boil will have more of their alpha-acids converted to the bitter form. However, hops also contain flavor compounds that are easily driven off by the high temperature of the boil, so hops that are added towards the end of the boil will provide more of a fruity, floral character to the wort. Therefore, early hop additions are often called “bittering” additions, while late hop additions are often called “aroma” additions. Boiling sterilizes the wort so that the microorganisms from the raw materials do not make it into the fermentation vessel. Boiling also causes protein to clump up so that it can be removed from the wort. The boiling step is around an hour to an hour and half long.

Fun Fact

In addition to providing bitterness, hop alpha-acids are also a preservative and can prevent bacterial growth in the final product!

After boiling, the wort needs to be clarified. At this stage, hop matter and protein will be starting to settle out of the wort, but must be left behind in the kettle and not carried over into the fermenter. To achieve this, brewers create a vortex in the kettle, like stirring a giant cup of tea. Once the whirlpool settles, the solid material will pile up in the center of the vessel in a cone shape and the clear wort can be drawn off the side. In larger breweries, this process happens in a separate vessel called the whirlpool, but in smaller systems this takes place in the kettle.

Yeast

Next, the clear wort needs to be rapidly cooled to approximately room temperature so that the final beer element can be added: yeast! Most of the time, a heat exchanger is used to accomplish the cooling. This piece of equipment has two channels: one for the wort being chilled and one for the cooling liquid. These channels are arranged so that the cooling liquid, usually water, travels in the opposite direction that the hot wort does, stealing its heat along the way. Oftentimes this water then travels to the hot liquor tun, where it can be used later for cleaning.

The wort, now at room temperature, travels to the fermentation vessel and yeast can be added. Here, the wort is left to ferment and is transformed into beer. Other processing can occur in the fermentation vessel, like dry hopping, where hops are added directly to the fermenting wort. This kind of extraction won’t add much bitterness, since there’s no heat to isomerize the alpha-acids into iso-alpha-acids, but it will add the delicate aromas and flavor compounds from the hops. At this point, the beer is almost ready to drink, but just a few steps remain before it can make its way to your pint glass!

Beer

Fermentation is a messy process and kicks up all kinds of material into the beer. This material, which includes yeast cells, proteins, and other particulate matter, creates a cloudiness in the beer and should be removed*. This process is known as clarification and can be accomplished several ways. The easiest—and oldest—way to clarify beer is to simply chill the beer and give it time, this is called lagering. Eventually, the material will settle out at the bottom of the tank and can be removed so only the clear beer remains. However, this process is time-consuming and takes up precious production space. Other methods of clarification used in craft breweries include filtering, fining, or centrifuging, which can clarify the beer in a much shorter amount of time. Ideally, the beer is crystal-clear at the end of clarification—*unless you’re brewing a Hazy IPA, of course!

Fun Fact

According to some sources, it was beer—not bread—that spurred early humans to cultivate grain, creating agriculture and society in the process.

Finally, the beer is ready to drink. To get it in the hands of customers, though, it needs to be packaged. Beer is usually packaged in kegs, bottles, or cans, and can then be sent wherever it needs to go. At last, the beer reaches its final destination. Through this long and winding path, the four elements of beer are woven together to create something truly spectacular. So next time you crack open a cold one, be thankful for all the time and effort that went into creating it!