Yeast 101

The Four Elements: Yeast

The beer… it’s ALIVE!

Toiling away in a brewery nearby, mysterious, cryptic creatures are working hard at one of the greatest jobs on earth: making beer. And no, we’re not talking about the brewing team! Who, then, has such an important task? Yeast! Although yeast is perhaps the most important and dynamic ingredient in beer, early brewers didn’t know anything about it! In fact, in the original version of the Reinheitsgebot, or the German Purity Law, yeast wasn’t listed as an ingredient since brewers were unaware of its existence.

Our scientific understanding of yeast began around the late 19th century with the research done by Louis Pasteur and Emil Christian Hansen, and soon after breweries began to incorporate this new knowledge. Today, our understanding of yeast continues to develop, and new strains are released all the time. But what makes yeast so important for beer production? Let’s look through the microscope and see!

Yeast is the living organism that turns wort into beer as it eats the sugar and turns it into alcohol and carbon dioxide. The alcohol, of course, is what drove early humans to keep making beer and helps to preserve the final product, and the carbon dioxide gives beer its bubbly head and also helps to prevent spoilage. Alongside ethanol and carbon dioxide, yeasts create all sorts of compounds that stick around after fermentation and contribute flavor and character to the beer. After the yeast consumes all the sugars that it can, it falls to the bottom of the tank where it can be collected and used for a future batch.

Fun Fact

Many brewers let their brews carbonate through the spunding process: after the bulk of the fermentation is complete, the fermentation vessel can be sealed up with a pressure relief valve which releases gas after a certain pressure is reached. As the yeast continues to ferment, the pressure rises in the tank and the beer is carbonated as the carbon dioxide is produced!

In addition to the wort sugars, yeast needs a few other crucial compounds to ferment at its best. For example, some metal ions are crucial for yeast metabolism since certain enzymes require them to function, such as zinc ions in Alcohol Dehydrogenase (ADH). For most minerals, more than enough is supplied by the malt but extra zinc is often added since it’s so critical for a healthy fermentation. Another example is a source of nitrogen, which is often measured as Free Amino Nitrogen (FAN). In beer production, FAN is provided as amino acids from the malt, but yeast can also process inorganic nitrogen in the form of ammonium ions. This is a whole other blog for later, but if you want to sound in the know, make sure you know the differences between FAN, PAN, and YAN!

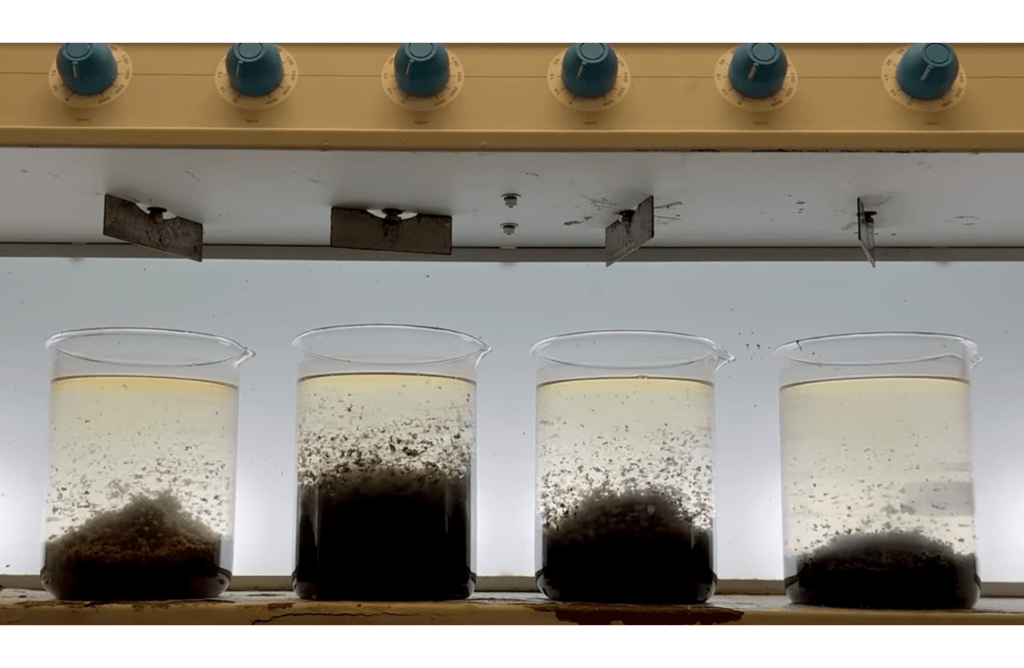

Brewers typically use one of two different yeast species when making beer: ale yeast, known as Saccharomyces cerevisiae, and lager yeast, known as Saccharomyces pastorianus. Ale yeast typically ferments at a higher temperature and faster than lager yeast, which prefers a colder fermentation temperature. Within each of these species exist hundreds of different strains, each with their own flavor profile and fermentation characteristics. In addition, different yeast strains have different flocculation characteristics, which is the tendency for yeast cells to clump together and form small “flocs.” The more flocculent a yeast strain is, the more likely it is to clump together and fall to the bottom of the tank, and the less flocculent a yeast strain is, the more likely it is to continue to float around in the beer after fermentation is done.

In addition to flocculation, yeast strains are generally categorized by a few other major details: preferred temperature range, alcohol tolerance, and attenuation.

- Preferred temperature range is simply the range of temperatures the yeast performs best at, and helps brewers determine how hot or cold to set their fermenters.

- Alcohol tolerance is the ABV level at which the yeast starts to die off, an important value to know for high-gravity brewing.

- Attenuation is a measure of how much of the sugar in wort can be converted to alcohol by the yeast. A low attenuation value means that the yeast will leave a significant amount of sugar in the beer, leading to a sweeter, richer brew. A high attenuation value means that the yeast can ferment more of the sugar in the wort, leading to a drier, crispier beer.

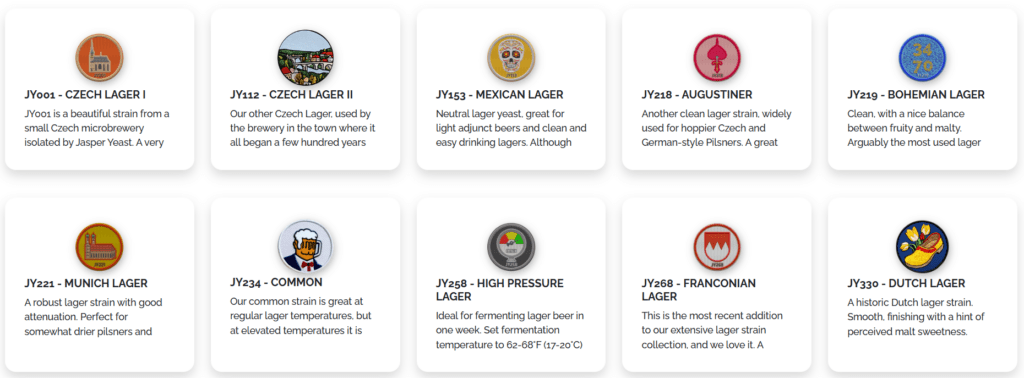

Brewers have been collecting and developing yeast strains for a long time, and historical styles are often defined by the yeast strain traditionally used to make them. These strains evolved along with different brewing traditions as brewers selected for better flavor, faster fermentation, or a higher alcohol production. For example, the yeast strains used in the Belgian brewing tradition commonly produce all kinds of spicy, fruity, and funky flavors that are a defining feature of beer styles like Belgian Wit, Saison, and Trappist styles. In the German brewing tradition, on the other hand, a clean fermentation profile is more common, and German yeast strains—especially lager strains—don’t produce as many potent flavor-active compounds.

Over the years, differences in brewing culture and tradition have created hundreds of different strains that are available to the modern brewer. But with hybridization strategies and genetic engineering technologies, yeast labs are taking it to the next level. Yeast strains can be designed to make all kinds of flavor compounds and enzymes. For example, a few different yeast companies now have strains specifically engineered to eliminate diacetyl from the final product. To do this, the yeast has been engineered to produce the Acetolactate Decarboxylase (ALDC) enzyme directly inside the cell. This enzyme breaks down Alpha-acetolactate before it can degrade into diacetyl in the first place, eliminating the need for a diacetyl rest. Between the traditional, engineered, or wild yeast strains, brewers have more options than ever before for fermentation partners.

With all the new yeast developments and breakthroughs, the possibilities are endless. Although the brew team makes the wort, the yeast is what turns it into beer! So the next time you enjoy a pint, be sure to give thanks to the billions of yeast cells that made it. Without their hard work, beer just wouldn’t be the same.