Bottling: Let’s talk about it. No reason to keep it bottled up.

The bottling process is a fragile part of winemaking. With the final product just in reach, it can be tempting to rush to the finish line. However, bottling is a delicate step of winemaking, and therefore should be treated as such. Afterall, everyone knows a winemaker’s greatest trait is patience!

Successful bottling methods will enhance a wine’s flavor and complexity. Throughout the bottling process, winemakers should be particularly mindful about preserving the wine’s original quality. In order to do so, winemakers should do their best to prevent over-oxidation. For more background on oxidization, check out our Wine Fermentation blog.

Preparing the Wine

Hold your horses! Before jumping to next steps, it is important to ensure your wine is ready for bottling. Keep in mind every wine is unique, and therefore some wines may need more attention than others. Below is a checklist of some of the most vital steps before bottling.

- Blending: Blending will help establish uniformity throughout the wine and help achieve the winemaker’s stylistic goals. For example, wines that are lacking color or acid content can be blended for correction.

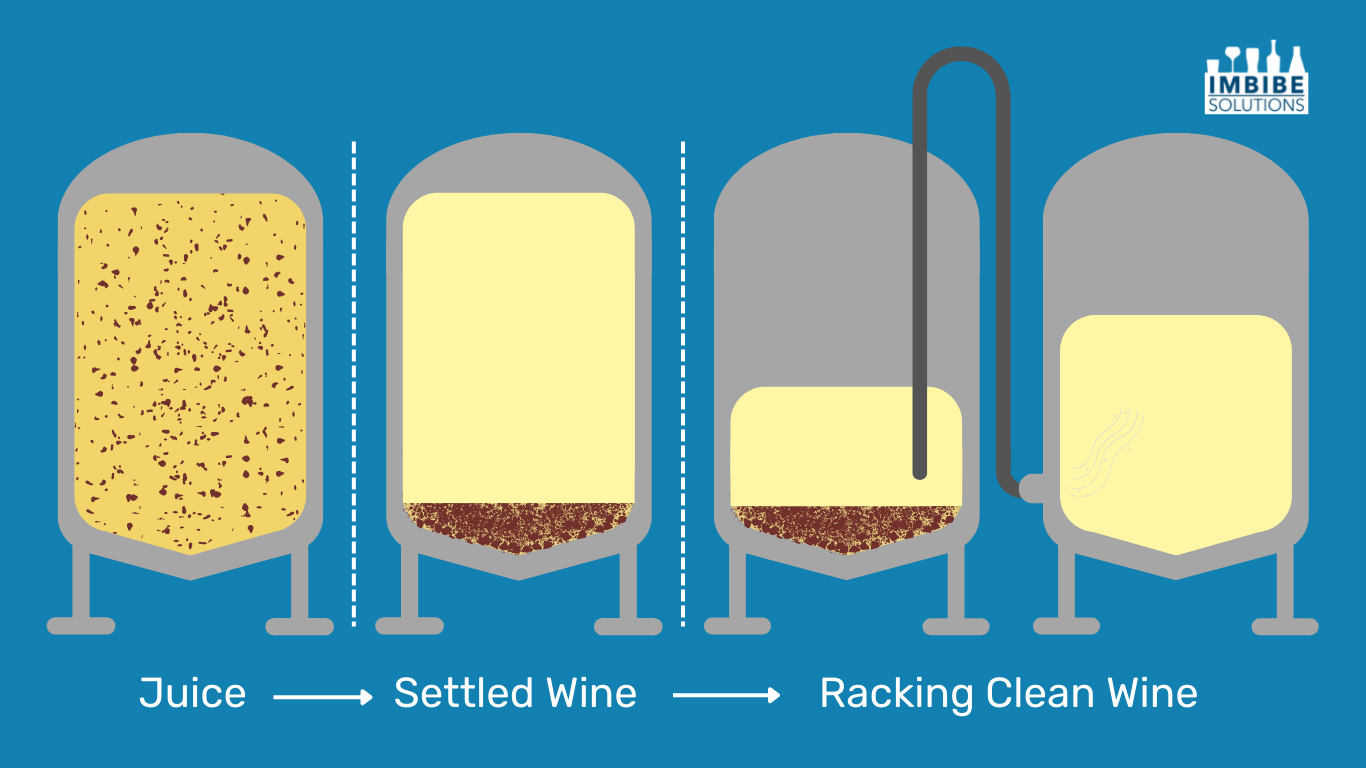

- Racking: Clarity is an important characteristic of the majority of wines. Throughout the fermentation process, sediment will fall to the bottom of the fermentation vessel and, if left in the wine, can create an undesirable aesthetic and disrupt the wine’s flavor. For these reasons, it is imperative for winemakers to rack their wine and discard the leftover sediment.

- Filtration: Filtration is typically recommended before bottling. Besides creating a crystal-clear wine, filters that are 0.45um can also remove yeast and bacteria from the wine. Removing these cells will significantly reduce the risk of spoilage in the bottle, especially in wines that have residual sugar or contain malic acid.

- Sterilization: It is important that bottling equipment (filters, hoses, pumps, bottling line, etc) are thoroughly cleaned before beginning. Bottles and equipment should be sanitized with a chemical solution like citric acid and sulfur before use. It is important since this is the LAST step before the wine gets sealed up. You want the customer to experience the awesome wine as it was intended.

- Sulfur Dioxide: For the majority of wines, additional SO2 is supplemented into the wine before bottling. Sulfur dioxide acts against unwanted oxidation and bacterial activity. To learn more about how SO2 acts as a preserving agent, check out our blog on wine aging.

- Heat/Cold Stability: Generally speaking, red wines will maintain heat and cold stabilization on their own. Unfortunately for winemakers, white wines and roses are not as cooperative. When wines are not heat stable, protein molecules will denature and create an undesirable haze. When wines are not cold stable, potassium bitartrate will precipitate out and form a crystal-like sediment. In order to attain clarity, most white wines must undergo filtering, fining, cold stabilization or combination of the three!

- Additives: To help winemakers meet their vision, additional products may be used to remove or add characteristics to the wine. Egg whites, gelatins, and isinglass are common additives used to increase fullness and mouthfeel, remove stringencies, remove color, and/or remove oxidation. It is highly recommended that a bench trial is set up before making additions to the bulk wine to hone in on ideal add rates. Consult the product package or your rep for instructions on doing so.

- Gases: It is good practice to know the gas volumes in your wine before packaging. One gas to check is the dissolved oxygen (DO) concentration. You want to make sure the wine’s DO level is as low as possible going into the bottle so as not to shorten the shelf-life with early oxidation. Another gas to regulate is carbon dioxide (CO2).

Packaging Materials

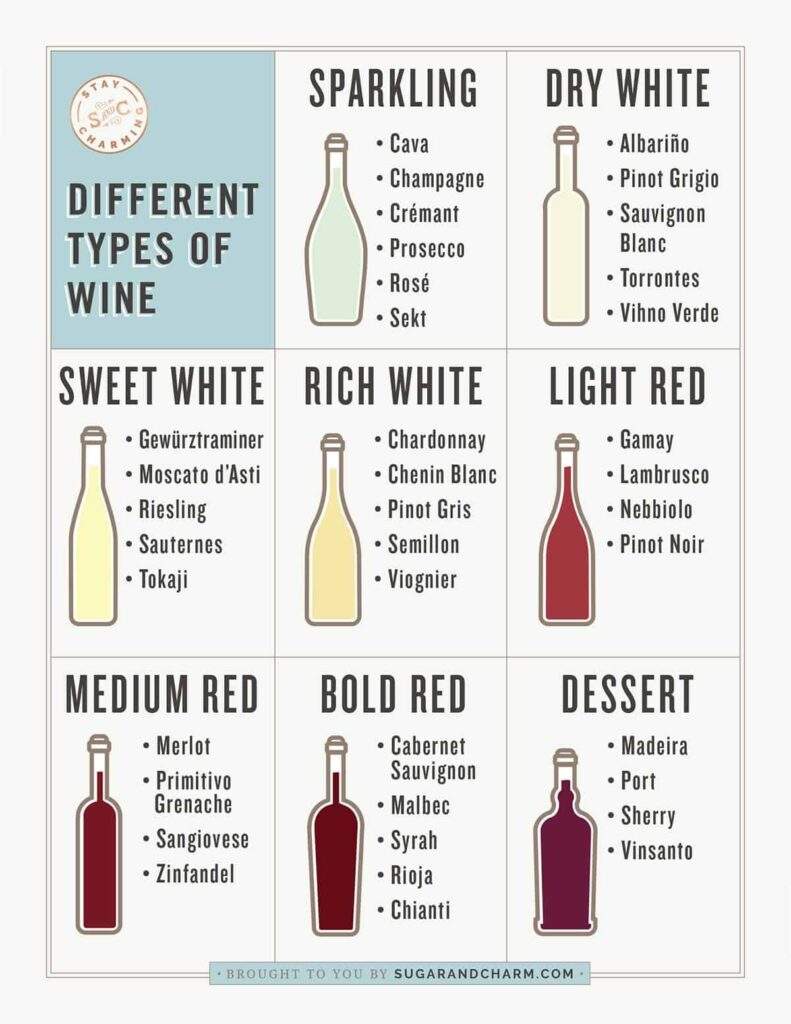

Bottles: A bottle’s shape and color are often determined by the variety of wine and region of manufacturing. For example, it is customary that white wines are bottled in brown, green, or blue bottles to inhibit light absorption from altering the wine’s chemical makeup. Although there has been some experimenting with alternative packaging like plastic wine bottles, bag-in-box, and cans, glass wine bottles are customary to the winemaking tradition.

Closures: There are two main types of wine closures: screw caps and corks. Screw caps are great for drink-now wines because they are easy-open. Corks are best suited for wines that will be aged in the

bottle because they allow for slight oxygen ingress. Red wines can be aged in the bottle for a long, long time, which is why most of these wines are sealed with corks (usually 2 inches long or longer).

Bottling Day

Preventing Oxygen: Throughout the bottling process, winemakers should try their best to limit the wine’s exposure to oxygen. When an excessive amount of oxygen is dissolved into the wine, it can distort the wine’s chemical makeup. Which in turn, can alter the wine’s shelf life, taste, and aesthetic (for more information about why this is, here is the link to our aging blog). The bottling process does not make this easy for winemakers… which means it’s time to put your winemaking skills to the test!

Filling: There are many ways to fill a bottle. Whether conducted manually or through automation, the bottling process may consist of different operations. These may include, gas purging (aka bottle deaeration), bottom-filling tubes or airtight sealed fill nozzles, gravity fillers or pressurized fillers, pre-closure gas injection, vacuum corking or crown corker or screwcap corker. Winemakers should be extremely cautious about oxygen pickup during this process. For example, any form of careless splashing in a non-purged bottle can interfere with the entire process (no pressure or anything…).

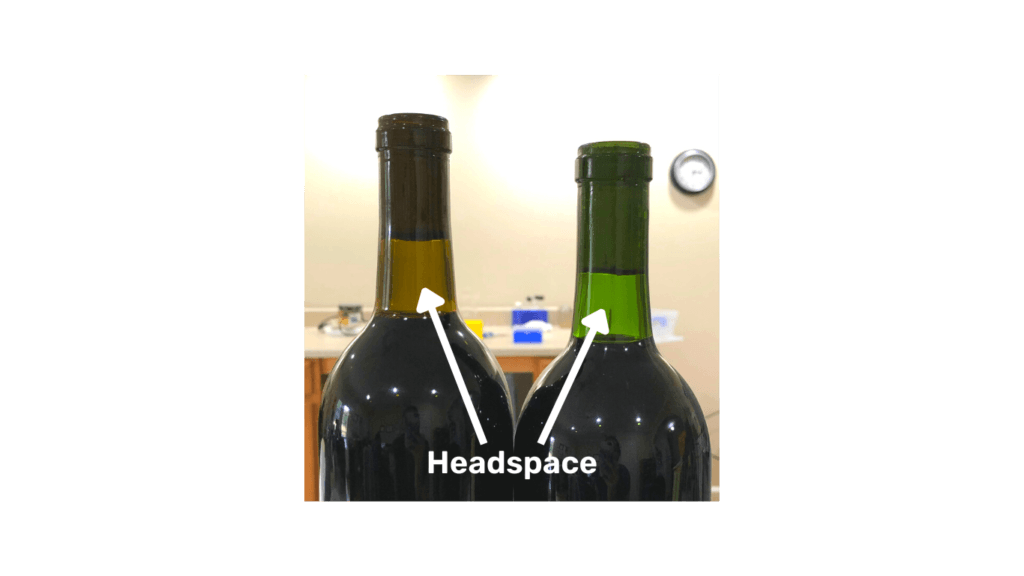

Headspace: Oxidation may occur based on the bottle’s headspace. The headspace refers to the open space between the wine and the cork or cap. If the bottle is improperly filled, this oxygen-rich gas can greatly affect its composition. However, a limited amount of air space is necessary for the wine to continue to age. Headspace can also help level out the wine if storage temperatures fluctuate (which they really shouldn’t). Ideally, an inert gas, like nitrogen or carbon dioxide, will be introduced before sealing to remove any oxygen present and help preserve the wine.

Post Bottling

After the wine is capped, the label is applied and the bottles are ready to be packaged and shipped. About time! Bottles should be stored on their sides or upside down in a temperature-controlled space to maximize shelf stability and aging potential. To learn more, check out our blog about proper wine cellaring conditions.

Just when you think the wine is finally finished… think again! While in the bottle, chemical reactions are still occurring after bottling, allowing the wine to deepen its flavor even further.

To see the bottling process in action, give this video a watch!

Additional Resources

“Aging and Bottling.” Encyclopædia Britannica, Encyclopædia Britannica, Inc., https://www.britannica.com/topic/wine/Aging-and-bottling.

Letaief, Hend. “Key Points of the Bottling Process,” May 2016, https://winesvinesanalytics.com/features/article/168227/Key-Points-of-the-Bottling-Process.

Drevescraft, Jim. “Bottling, Start to Finish.” WineMakerMag.com, 30 Mar. 2022, https://winemakermag.com/article/102-bottling-start-to-finish.