Staying Legal: TTB Limits on Additives and Processing Compounds

Navigating the complex landscape of alcohol production can be both nerve-wracking and challenging, especially when it comes to adhering to regulatory standards. The U.S. Alcohol and Tobacco Tax and Trade Bureau (TTB) plays a pivotal role in setting and enforcing boundaries that ensure your wine, beer, spirits, and cider remain within legal limits while achieving the desired quality. For producers, understanding these TTB regulations is crucial, as they define permissible levels of key compounds such as alcohol, sulfites, copper, and volatile acidity. This guide aims to demystify these product limits, offering quality control insights that transform regulatory compliance from a daunting task into a tolerable part of your craft. So, whether you’re a seasoned winemaker or a budding cider enthusiast, let’s dive into the essentials that keep your creations both delectable and legal.

Understanding TTB Regulations for Alcohol

In the world of alcohol production, TTB regulations serve as the guiding principles that ensure products meet safety and quality standards. These regulations are essential for maintaining consistency and legality across the board. By understanding the key components overseen by the TTB, producers can navigate the complexities of compliance more effectively.

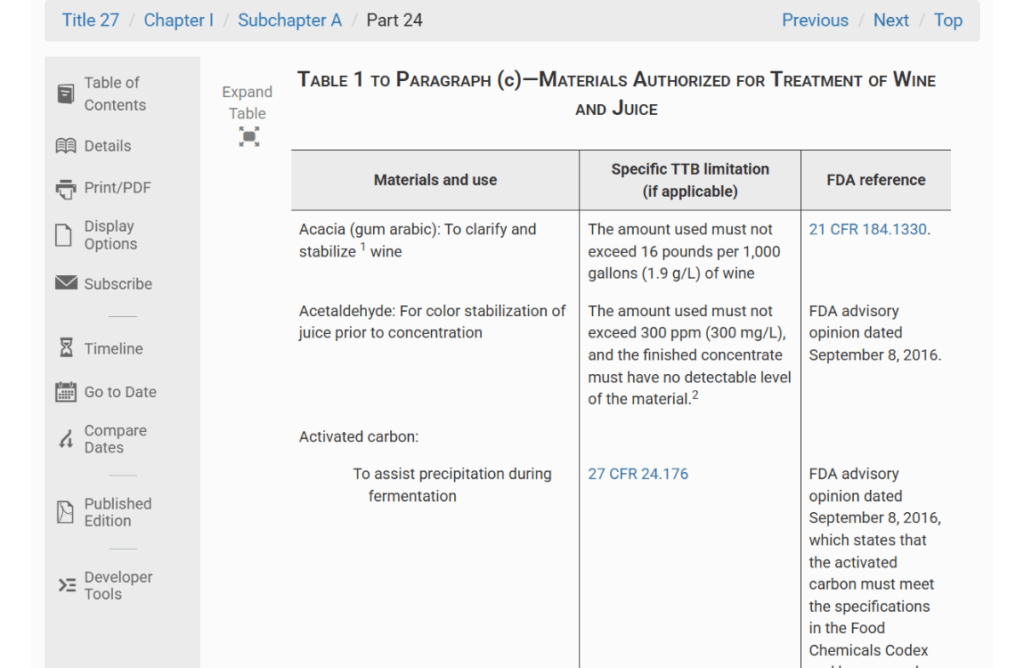

Ever wondered where these intricate TTB guidelines actually originate? They are derived from the Code of Federal Regulations (CFR), which serves as a massive rulebook for nearly every aspect of daily life in the U.S. (Think of it as the meticulous playbook crafted by those legal eagles to keep things in line.) Specifically, TTB’s rules are tucked away in Title 27, all set to ensure our boozy endeavours don’t turn into law-breaking escapades. We have linked each section to its applicable legal jargon – in case reading legal jargon is your thing.

Key Quality Control Data Points

Quality control in alcohol production involves monitoring several critical compounds. For instance, in wine production, the levels of sulfites, copper, and volatile acidity are tightly regulated. These components are vital in preserving the wine’s flavor and ensuring its safety for consumption.

In beer production, the primary focus is on the alcohol by volume (ABV), which must adhere to specific limits to meet TTB standards. This ensures the consumer receives a consistent product every time.

Spirits require careful monitoring of ammonium and copper sulfate to prevent impurities that can affect taste and quality. These compounds must remain within legal thresholds to avoid regulatory issues.

Cider producers also need to keep an eye on carbon dioxide levels, as excessive carbonation can lead to packaging failures and safety concerns. Understanding these data points is crucial for maintaining product quality and compliance.

The Role of TTB in Regulation

The TTB plays a pivotal role in ensuring that alcoholic products adhere to legal standards. Their guidelines cover everything from labeling to ingredient limits, ensuring transparency and consumer safety. The regulation process involves rigorous checks and balances.

1. Formula Approval: The TTB reviews and approves the ingredients used in alcohol production to ensure they meet safety standards. This is crucial for maintaining public health.

2. Compliance Checks: Regular inspections and audits are conducted by the TTB to ensure that producers remain compliant with set regulations. This keeps the industry accountable.

3. Education and Resources: The TTB provides resources such Beverage Alcohol Manuals (BAMs) for Distilled Spirits, Malt Beverages, and Wine to help producers understand and comply with their regulations.

Through these measures, the TTB ensures that the alcohol industry operates smoothly while protecting consumers.

Navigating Wine Additives and Limits

Wine production involves a delicate balance of additives and compounds that contribute to its unique flavor and quality. Understanding the legal limits and roles of these additives is essential for compliance and excellence in winemaking.

Reminder: The TTB definition of a wine is broad and is not limited to grape products!

“When used without qualification, the term includes every kind (class and type) of product produced on bonded wine premises from grapes, other fruit (including berries), or other suitable agricultural products and containing not more than 24 percent of alcohol by volume. The term includes all imitation, other than standard, or artificial wine and compounds sold as wine. A wine product containing less than one-half of one percent alcohol by volume is not taxable as wine when removed from the bonded wine premises.” – 27 CFR 24.10 “Wine”

Managing ABV, Volatile Acidity, and SO2 in Wine

Alcohol by Volume (ABV) is clearly a major factor in wine production, influencing both flavor and balance. Managing ABV within TTB limits is essential for not only compliance and tax purposes, but also for meeting consumer expectations.

| Alcohol by Volume (ABV) | Tolerance |

|---|---|

| Wines more than 14% ABV | 1.0% |

| Wine less than or equal to 14% ABV | 1.5% |

| Wines less than 7% ABV | 0.75% |

Fun Fact

Wine has the largest ABV tolerance among alcoholic beverages. Way to go, wine lobby.

Volatile Acidity (VA) affects the aroma and taste of wine. High VA levels can result in undesirable footie or vinegar flavors, making it crucial to adhere to legal limits. The federal maximum for VA in wines, calculated as acetic acid and exclusive of sulfur dioxide, specifies limits for various types of wines.

| Type of Wine | Limit (g acetic acid/100 mL) |

|---|---|

| Red, dry, natural* wines | 0.140 |

| White, dry wines, and other wines | 0.120 |

| Ameliorated juice (28+ degrees Brix) | 0.17 for red, 0.15 for white |

| Natural* fruit wines | 0.14 |

| Other fruit wines | 0.12 |

*Natural is defined as a wine with no added brandy or alcohol

Sulfur Dioxide (SO2) is a key preservative in wine, preventing oxidation and bacterial growth. However, excessive levels can lead to off-flavors and health concerns. TTB regulations specify that the legal limit for SO2 in wine is 350 parts per million (ppm) to ensure safety.

Other Wine Additives: Copper, Ammonium, and Potassium Bitartrate

Copper is used to remove hydrogen sulfide from wine, but it must be carefully monitored to prevent toxicity. The TTB specifies that the legal limit for copper added to wine must not exceed 6 ppm (6 mg/L) and the residual level in the finished wine must not be greater than 0.5 ppm (0.5 mg/L) to maintain quality without compromising safety.

Ammonium is another critical component, aiding in yeast nutrition during fermentation. Its levels must be balanced within the legal limit for ammonium in wine of 0.96g/L (8 lbs/Kgal) to enhance fermentation without affecting the end product negatively.

Potassium bitartrate, also known as cream of tartar, is used in wine production to ensure cold stability and to prevent crystallization in the bottle, which could be mistaken for glass shards. The amount used must not exceed 4.19 g/L (35 lbs/Kgal), although anything near this level is generally considered excessive for this process.

Carbon Dioxide Considerations For Cidermakers

While cider is classified as a wine in most circumstances, there is one important limit that is unique to hard cider: carbon dioxide.

Carbon dioxide is a key characteristic for many ciders, influencing both taste and mouthfeel. The TTB provides guidelines on permissible CO2 levels to prevent over- and under-carbonation, which can lead to packaging issues and safety hazards.

Whether a hard cider is naturally or artificially carbonated, it must contain between 3.92 and 6.4 g of carbon dioxide per liter. (For those of you that work in Volumes, that is 2-3.27 vol.) Any less than 3.92 g/L and the cider is considered ‘still’.

Beer and Spirits Compliance

In addition to wine, beer and spirits also fall under TTB scrutiny. Understanding the most significant regulations for each category is fundamental for compliance and production excellence.

Monitoring Beer ABV

In beer production, ABV is a critical measure that impacts both flavor and strength. The TTB outlines clear regulations on ABV to ensure consistency and legality with strict tolerances.

| Malt Beverage Category | Label ABV | Tolerance |

|---|---|---|

| 0.5% or More ABV | ≥ 0.5% ABV | ±0.3% ABV |

| “LOW ALCOHOL” Label | ≤ 2.5% ABV | ±0.3% ABV |

| “REDUCED ALCOHOL” Label | ≤ 2.5% ABV | ±0.3% ABV |

| Less than 0.5% ABV | < 0.5% | Must not exceed labeled ABV |

1. Measuring ABV: Accurate measurement of ABV is essential for compliance. While the potential alcohol calculators are great, they can’t always account for variables in fermentation, barrel aging, or hop creep. Testing is the only sure way to verify how much alcohol is present.

2. Labeling Requirements: Beer labels must clearly indicate the ABV and have a small window of tolerance of only ±0.3% ABV.

3. Consistency: Maintaining consistent ABV across batches is crucial for brand reliability. Discrepancies can lead to regulatory issues and consumer dissatisfaction.

Understanding and following these guidelines assists beer producers in maintaining both quality and compliance.

Spirits ABV, Copper Sulfate, and Ammonium Tolerance Levels

Alcohol by Volume (ABV) is an essential measure that determines both the potency and the profile of the beverage. Maintaining the correct ABV is critical for compliance with TTB regulations. The TTB specifies allowable tolerance levels for spirits, which provide a small window for variance to account for natural discrepancies during production. This tolerance facilitates regulatory compliance while ensuring the product remains consistent with consumer expectations.

| Condition | Tolerance |

|---|---|

| Spirits containing solids in excess of 600mg/100ml | 0.25% ABV |

| Spirits bottled in 50ml and 100ml containers | 0.25% ABV |

| All other spirits | 0.15% ABV |

Copper sulfate is used to eliminate hydrogen sulfide and mercaptans in brandy and wine spirit base materials. Thus, it is imporant to make sure minimal amounts are transferred during distillation. The CFR cites the Generally Recognized As Safe (GRAS) level established by the FDA advisory opinion of 7/23/69, which says that finished products may not contain more than 2 parts per million (2 mg/L) residual copper.

Ammonium phosphate/diammonium phosphate plays a crucial role in supporting yeast health during fermentation, which in turn affects both the taste and the alcohol levels of the distilled beverage. The usage limit is set at a maximum of 1.2 g/L (10 lbs/Kgal).

Keep It Legal – and Delicious

Understanding and adhering to TTB regulations is not just a legal obligation—it’s a pathway to crafting exceptional beverages that consumers will love and trust. We have only listed the most common legal limits you may run into during production. Be sure to follow TTB guidelines for all additives you are using. By mastering the guidelines on additives and processing compounds, you can ensure your creations meet the highest standards of quality and safety.

So, keep that creativity flowing and your fermentation tanks bubbling. Remember, compliance is just another ingredient in your recipe for success. For any questions or testing needs, our lab doors are always open. Let’s toast to your next big batch of brilliance—may it be both legally sound and exceptionally delicious. Cheers to crafting with confidence and joy! 🍻🍷🥂